Trust Martin Safety for a Safer Workplace

Martin Supply’s team of highly-skilled safety experts assist you in selecting the appropriate safety solution for PPE, facility safety, safety equipment, OSHA and general training, inspections, and PPE fit testing. Our partnerships with hundreds of leading safety supplier brands, give us and you access to the right safety products that meet your specific needs.

Let’s work together to protect your workers.

Contact A Martin Expert Today.Safety Training and Inspections

Are you prepared for OSHA Inspection? Martin Supply offers OSHA-certified training courses and plant inspections that align with the U.S. Code of Federal Regulations for General Industry (29 CFR 1910) to enhance safety and compliance within your organization. From general safety trainings to fall protection, Martin has the safety solution to fit your needs.

Explore our safety training services.

LEARN MORE

Safety Vending Services

Martin Supply offers safety vending solutions to improve worker safety and eliminate inefficiencies. Our secure and easy-to-use vending machines eliminate inefficiencies, improve production flow and workplace safety.

Discover the best safety vending solution for your operation.

LEARN MORESafety Equipment Rental

Get access to safety equipment as you need it, without making a large financial investment. Martin Supply’s extensive collection of rental equipment offerings caters to specialized equipment needs for any safety-related project.

Explore our safety equipment rental options.

LEARN MORE

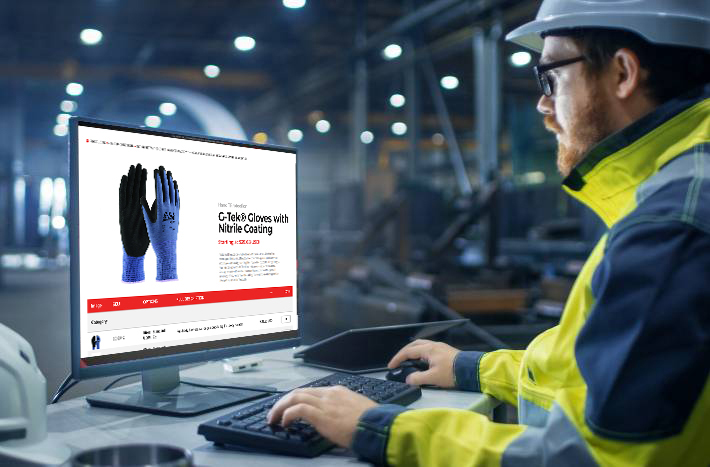

Custom e-Catalog Solution

Reduce rogue spend and stay within budget. For customers looking for a smart and efficient e-commerce buying solution, we create a customized and vetted customer portal and catalog that features regularly purchased items at dedicated pricing for a fast and easy purchasing experience 24/7.

Customize your e-Catalog solution today.

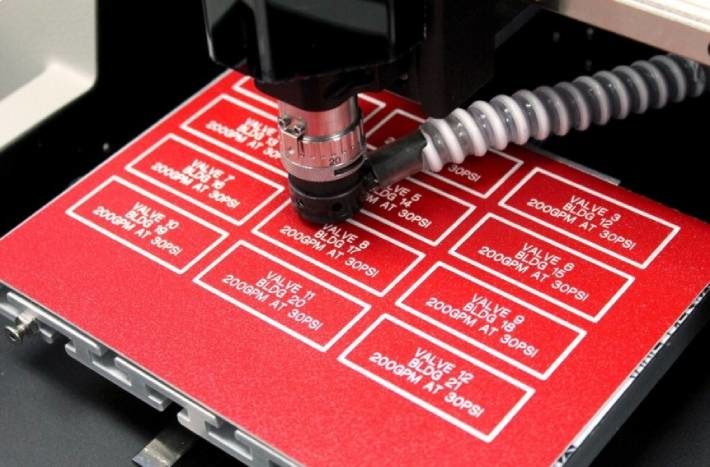

LEARN MOREEngraving Services

Martin offers premium laser engraving services customized to your company’s needs. Our versatile system enables us to engrave, cut or mark anything from lockout/tagout tags and valve tags to customized messages on a variety of surfaces. Let our specialists help you find the right materials and solutions for any application.

Improve safety and compliance in your operation.

LEARN MORE

Safety Solutions Case Studies

We help companies improve their safety, productivity and performance with

custom tailored solutions. Read some of our safety success stories.

Lockout/Tagout Case Study

OSHA cited a major food and beverage manufacturer for lack of training and inadequate lockout procedures. Though they had limited resources and time, Martin connected them with Brady’s software and training programs for machine-specific procedures and access — completing implementation within eight weeks and meeting their OSHA deadline.

Safety Gloves Case Study

Martin partnered with Ansell Gloves to deliver a patented productivity improvement program that focuses on safety and compliance, productivity and cost performance, saving companies on average $65,000 per assessment while experiencing 65% reduction in injuries.

Safety Training Case Study

The safety team at a major manufacturer was struggling to provide in-depth safety training to employees while focusing on the company’s EHS issues. After collaborating with Martin’s OSHA-licensed trainer, we custom tailored a training plan to meet their needs and decrease recordable injuries.