ByMartin Supply •

The Importance of a Clean Storeroom

When you think about your storeroom, what comes to mind? Is it crisp, straight lines, clear floors, and well-marked shelves?

Or does your storeroom looks something like this?

If you identify with these pictures don’t worry, because you aren’t alone. However, it is important to understand the value is of maintaining a clean work space and the processes necessary for improvement.

It may seem like it doesn’t matter what the storeroom looks like. After all, most people don’t really see it, and as long as we know what’s in there, who cares, right? Studies have shown that this is not the case. In fact, have a clean, well-organized storeroom is critical to maximizing the storeroom’s value.

These benefits include:

- Higher Fill Rate and Accuracy – know at a glance what’s on the shelf

- Increased Productivity – less time spent searching

- Reduced Cost – products don’t get damaged or lost

- Greater Safety – with everything in order there is less risk of slips, trips, falls, or items dropping

In Martin’s experience, the best way to achieve these results is with a robust 5S program.

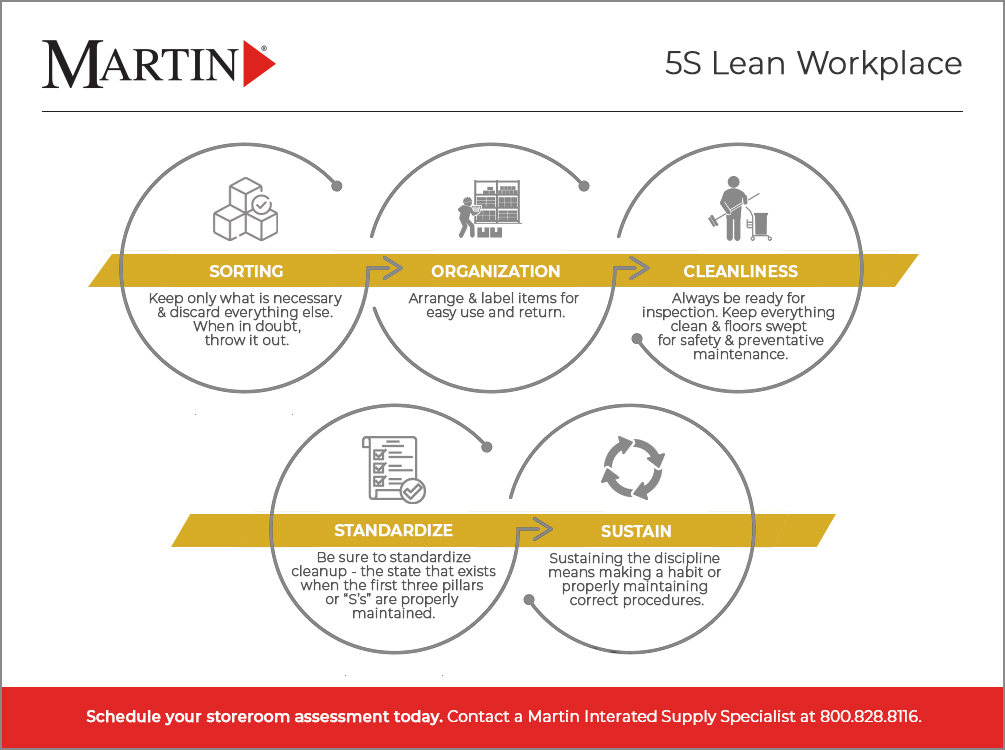

What is 5S?

5S is a system rooted in lean concepts that is designed to keep work spaces organized so that work can be done efficiently, effectively, and safety. Here is a brief rundown of the methodology:

5S LEAN WORKPLACE

- Sort

Organization – keeping only what is necessary and discard everything else – when in doubt throw it out - Set in Order

Orderliness – arranging and label only necessary items for easy use and return by anyone in the plant or facility - Shine

Cleanliness – keeping everything swept and clean for inspection – for safety and preventative maintenance - Standardize

Standardized clean up – the state that exsists when the first three pillars or “S’s” are properly maintained - Sustain

Sustaining the discipline – making a habit of properly maintaining correct procedures

At Martin Integrated Supply, every storeroom that we operate utilizes the 5S process and makes cleanliness a priority. We have standards that we set, audit, and report for each site so that our customers are confident that their storeroom is running at peak efficiency.

To find out more, contact Martin to schedule your assessment and find out how a clean storeroom helps you operate better.

Comments for this post are closed.