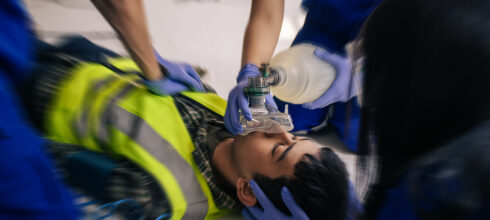

From Harmless to Hazardous: The Tipping Point in Toxic Exposure

Even everyday substances like water or cleaning agents can become toxic at high exposure levels. Learn how safety managers can monitor and prevent overexposure in industrial environments. Read more about From Harmless to Hazardous: The Tipping Point in Toxic Exposure