ByMartin Supply •

Cutting Costs Without Cutting Quality by Reviewing Your Tooling

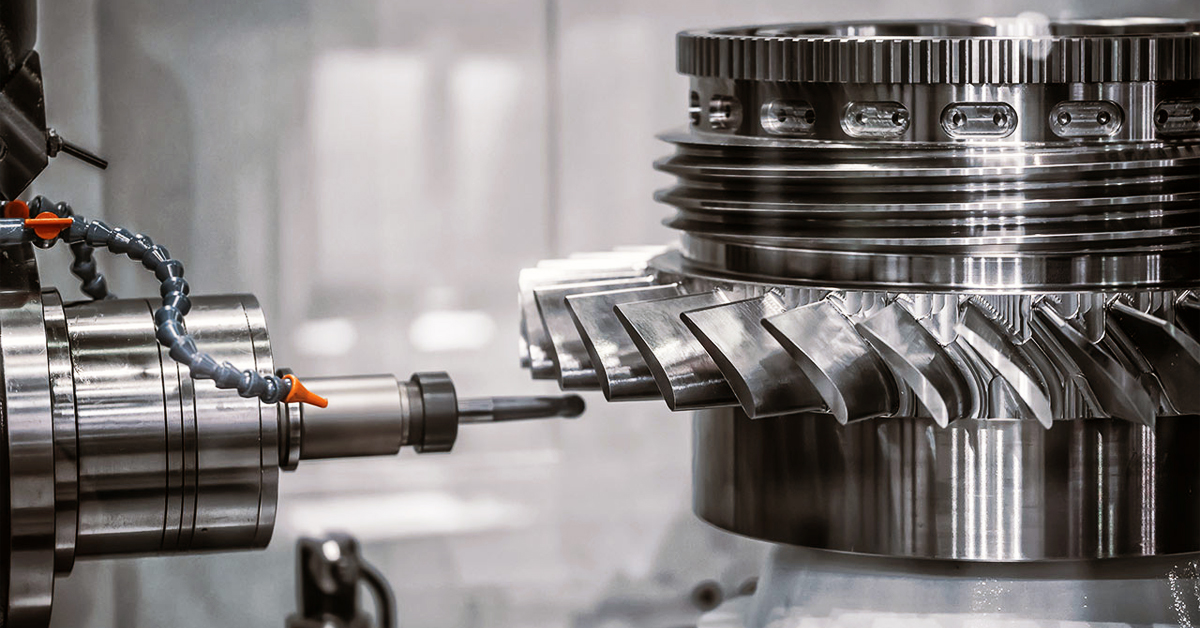

Choosing the correct tool for your facility is a tough balancing act. Choosing a quality item that fits your needs without breaking the bank can be a long and complicated process. An aerospace machining shop approached Martin Supply to help find a new tool that could cut their annual costs without sacrificing quality to combat the rising material prices. Due to the tight restrictions of the aerospace industry, options for a quality solution were reduced even more.

Martin’s Expert Intervention

Martin’s team of metalworking specialists began their process by reviewing the existing tooling inside their facility. Collaborating with a cutting tool expert and a trusted manufacturer, they made a comprehensive assessment of their tooling to find opportunities for savings. After rigorous testing and analysis, Martin’s team was able to find a milling application in their facility where the tool life was poor. With a simple replacement, Martin’s team believed that they could significantly extend the life of their tools, which would cut long-term costs and reduce downtime.

Reducing Costs and Doubling Tool Life

Following the replacement, early returns were very positive. The cost per component was reduced by 39% and tool life was roughly double compared to the original tool. In total, the aerospace machine shop is saving almost $20,000 annually after the replacement. Martin also swapped out the cutter at no charge to the customers, making the transaction seamless and easy without disrupting their operations.

Moving The Bottom Line

As industries navigate the challenges of rising costs and increasing demands for precision, partnerships with trusted advisors like Martin prove instrumental in unlocking hidden opportunities for optimization. By leveraging expertise and innovation, businesses can not only weather challenges but emerge stronger, more efficient, and better positioned for sustained success.

This example shows why it’s important to review your own processes and continuously look for ways to improve. Martin’s custom-tailored solution not only addressed the immediate need for cost reduction but also bolstered the shop’s competitive edge in the aerospace machining industry. To learn how Martin can help you, contact your Martin Sales Rep or call 800.828.8116.

Comments for this post are closed.